Since its foundation in 2005, FENZO has aimed at designing and manufacturing high precision workholding devices for CNC machining and other processing operations. Today, we have grown into a domestically leading workholding tools manufacturer with abundant resources covering partnered R&D institutes, sales network, media platform and database. We offer complete workpiece clamping solutions that are precisely oriented to the industrial processing needs for quick, secure and precise workpiece workholding.

FENZO’s a broad variety of workholding devices includes swing clamps, link clamps, hydraulic workholding cylinders, work supports, hydraulic control valves, rotary joints, etc. Our workholding tools give customers access to a wide selection of clamping options available, enabling them to keep costs down while adapting to their changing needs. Our nearly 20 years experience means we understand workpiece clamping field and our expertise now spans across a diverse range of market segments. FENZO has so far served customers in variety of end-markets, including automotive, marine, agriculture, home appliance, valve, pump and more. In addition to our portfolio of standard workholding devices, we can also supply customer-specific workpiece clamping products which are modified on the basis of standard versions in terms of appearance and installation method to adapt to customers' individual demands, with results satisfying the expectations of our customers while meeting our rigid standards of excellence.

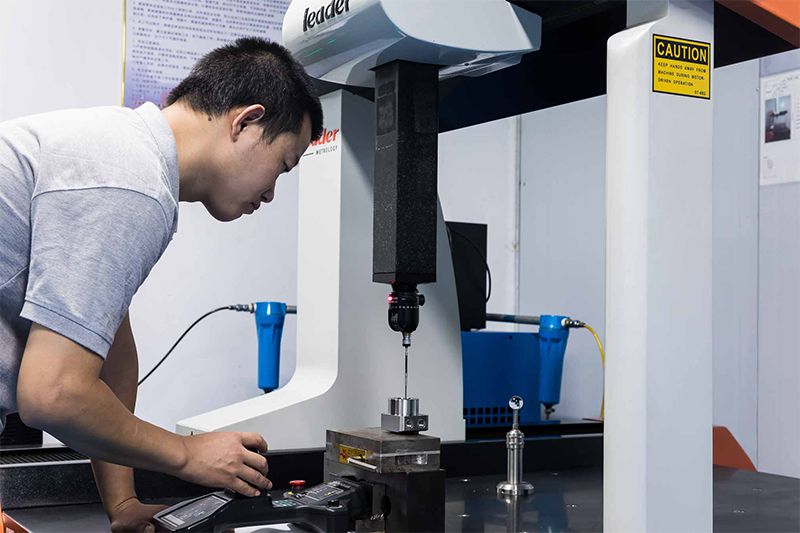

At FENZO we use high precision manufacturing equipment such as CNC machining center, CNC turning milling machine and CNC lathe, along with cutting-edge testing and inspection equipment like multi-station coordinate measuring machine, profile projector and hardness tester, to ensure that all our workholding products are manufactured in accordance with stringent guidelines through each step of rough processing, heat treatment, fine processing, surface treatment, assembling and 100% pressure testing.

Thanks to our R&D team of 15 experts who have been constantly pushing the limits of innovation, we are granted 6 to 8 new patents every year. This ensures we maintain a leading position within the domestic market, and have the ability to take the production of our customers ahead in their competitive market.

FENZO is based in Beilun District, a district of Ningbo in Zhejiang province, which is well recognized as a hometown of molds. With its location near the international Beilun port, the geographical advantage allows us to fast delivery of products. Besides, our engineers are available around the clock for the after-sales services.